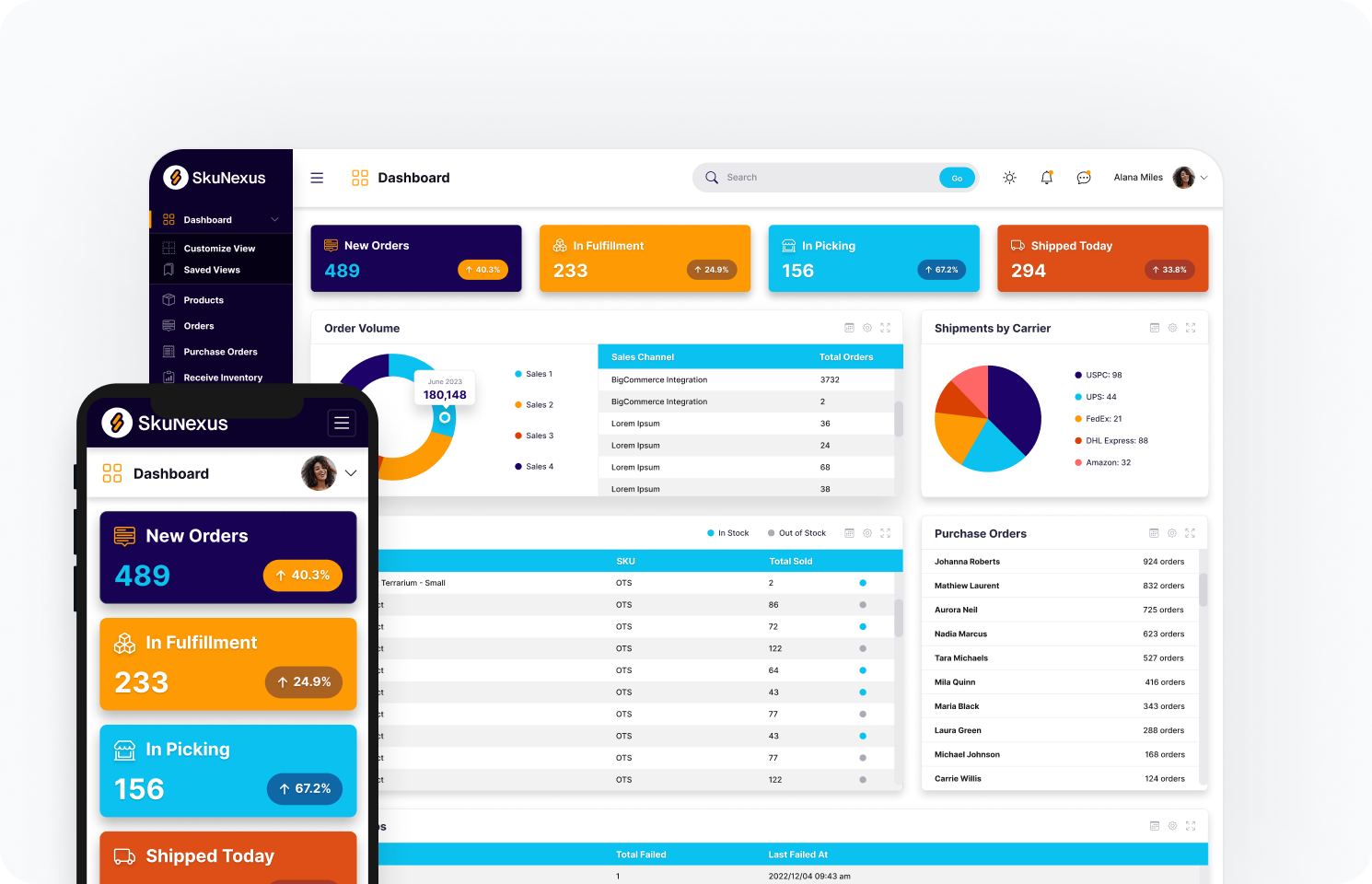

SkuNexus is an order management system that allows users full access to the source code, allowing complete control.

7400 Skokie Blvd, Skokie, IL 60077.

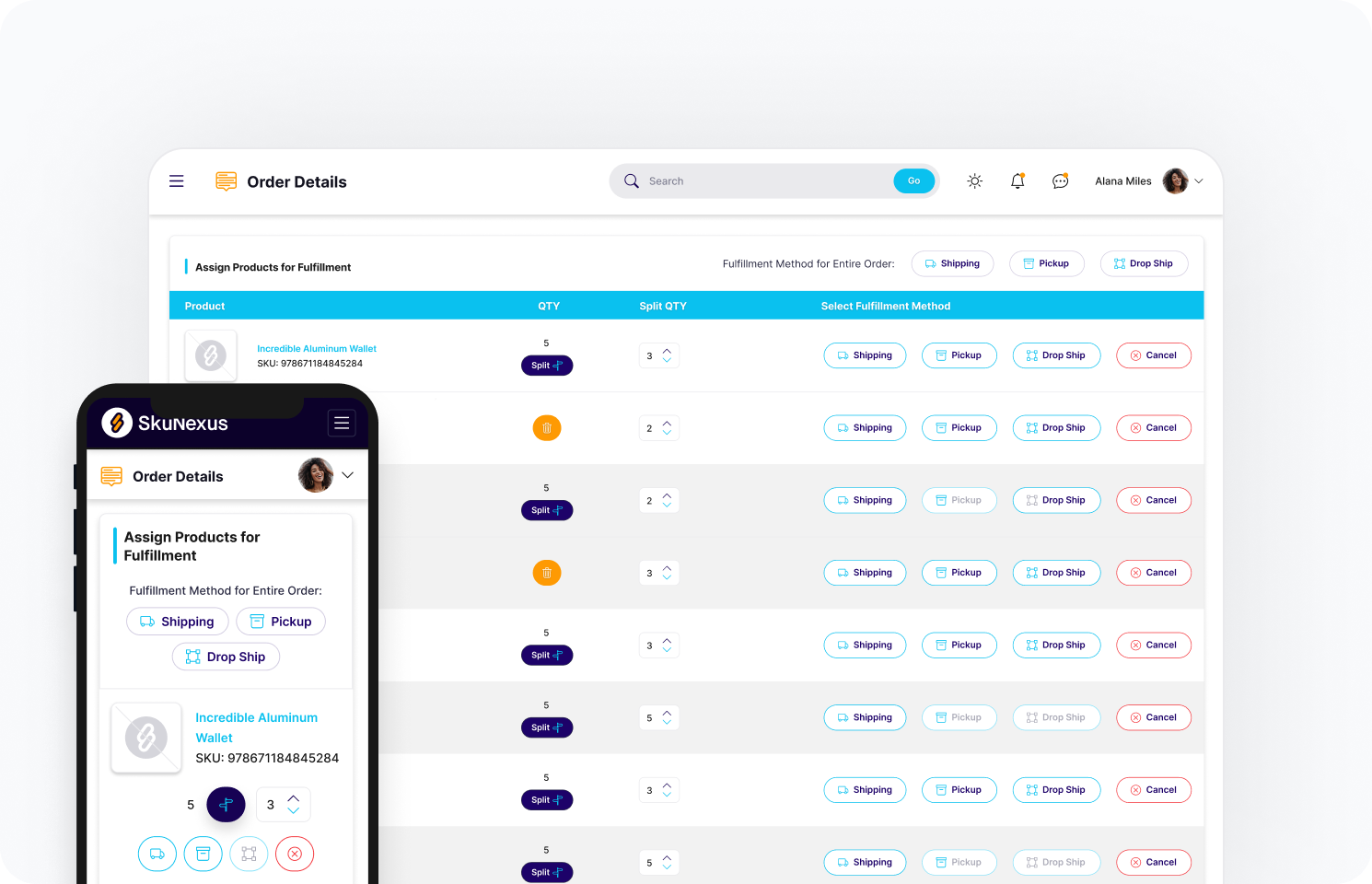

Zero paper. Zero guesswork. SkuNexus automates your entire fulfillment process from the moment an order arrives to the moment it leaves the dock. Pick, pack, verify, and ship without manual intervention.

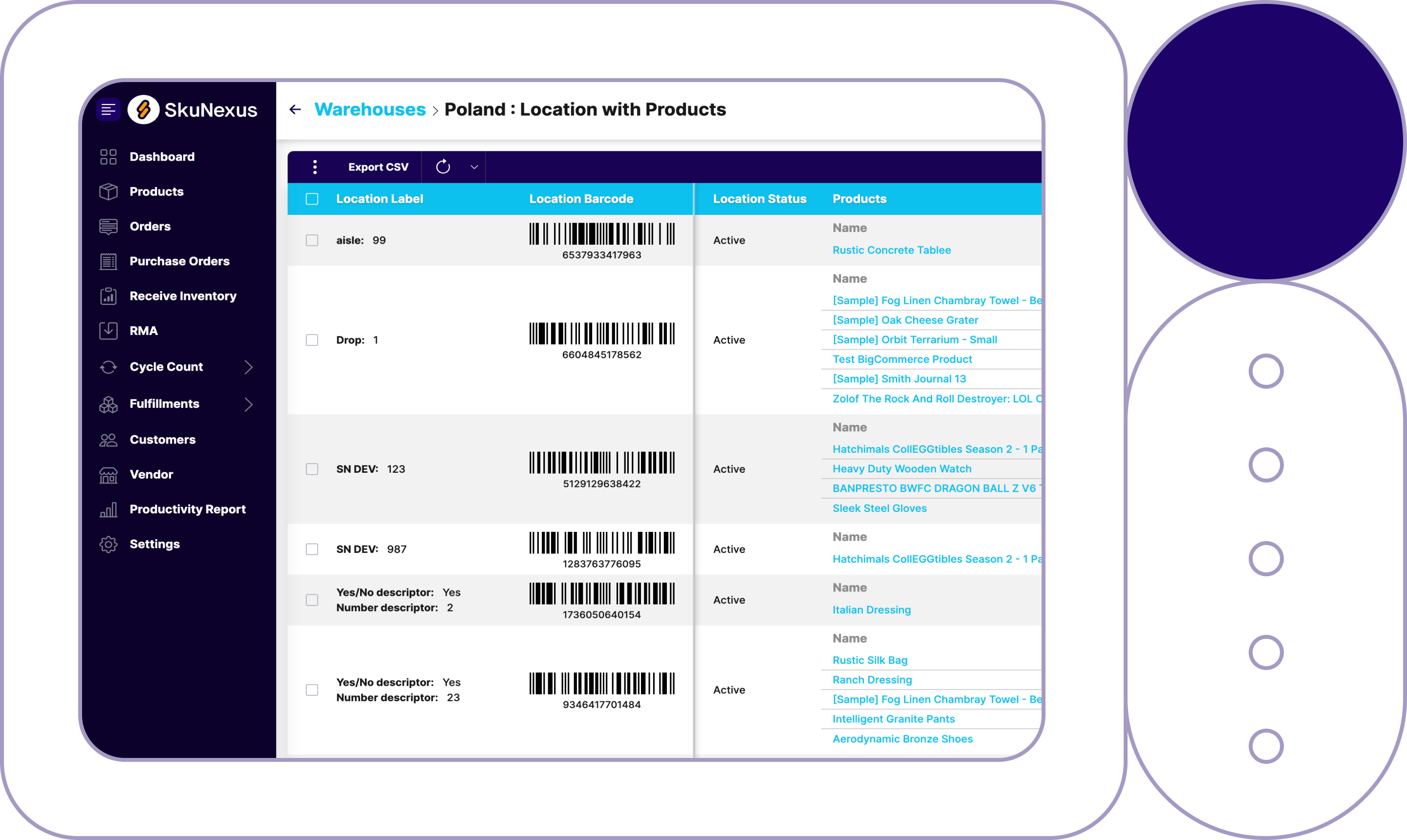

A warehouse management system (WMS) is software that controls and optimizes the movement and storage of goods within your warehouse, from the moment inventory arrives until it's ready to ship.

Traditional fulfillment relies on printed pick slips, manual carrier selection, and human decision-making at every step. That works at low volume, but it doesn't scale. Every manual touchpoint introduces delay and error. Modern Pick, pack, and ship software eliminates those touchpoints entirely.

Trusted by brands shipping thousands of orders daily

"We're printing hundreds of pick slips a day and still can't keep up."

Paper-based picking is slow, error-prone, and doesn't scale. Every printed slip is a manual process waiting to break down.

Paper Overload"We shipped the wrong item again. The customer is furious."

Without scan verification, picking and packing errors slip through. Every mis-ship costs you in returns, reshipping, and lost trust.

Shipping Errors"We just pick whatever carrier is easiest. We're probably overpaying."

Without rate shopping, you're leaving money on the table with every shipment. The savings add up fast.

Overpaying for ShippingSkuNexus automates the entire pick, pack, and ship workflow. No paper. No guesswork. Orders flow from receipt to shipped with minimal human intervention and maximum accuracy.

See the DifferenceEliminate pick slips entirely. Workers receive assignments on screen, scan to confirm, and move to the next task automatically.

Every pick and pack is verified by barcode scan. Errors are caught before they leave the building, not when customers complain.

Compare real-time rates from 150+ carriers instantly. Automatically select the best option based on cost, speed, or your custom rules.

A 150-year-old premium ice cream brand selling DTC, wholesale, and through national retail partners.

"Our Smoothest Peak Season Ever"

Real-time rates and label printing with 150+ carriers. Native integrations with leading eCommerce platforms.

Manual fulfillment processes don't scale. Every paper slip, every manual carrier decision, every unchecked order is a cost waiting to hit your bottom line.

| Manual Fulfillment | SkuNexus Pick, Pack & Ship |

|---|---|

| ✕ Print pick slips for every order | ✓ Zero paper, fully digital workflow |

| ✕ Pickers choose their own routes | ✓ Optimized picking paths and batching |

| ✕ Pack by memory, hope it's right | ✓ Scan-to-verify every item |

| ✕ Pick one carrier for everything | ✓ Rate shop 150+ carriers in real time |

| ✕ No visibility into worker performance | ✓ Real-time productivity tracking |

| ✕ Errors discovered by customers | ✓ Errors caught before shipment |

Every manual step is a chance for error and delay. Brands using SkuNexus achieve 99.9% ship accuracy while tripling throughput and cutting shipping costs by over 20%. That's the difference between surviving peak season and thriving through it.

Free demo • No credit card required

No. SkuNexus runs in any modern browser. Use tablets, phones, laptops, or dedicated terminals at pick and pack stations. Your existing barcode scanners and label printers work out of the box.

Still have questions?

Talk to Our TeamSee how SkuNexus can automate your entire fulfillment workflow from pick to ship.

SkuNexus is an order management system that allows users full access to the source code, allowing complete control.

7400 Skokie Blvd, Skokie, IL 60077.