SkuNexus is an order management system that allows users full access to the source code, allowing complete control.

7400 Skokie Blvd, Skokie, IL 60077.

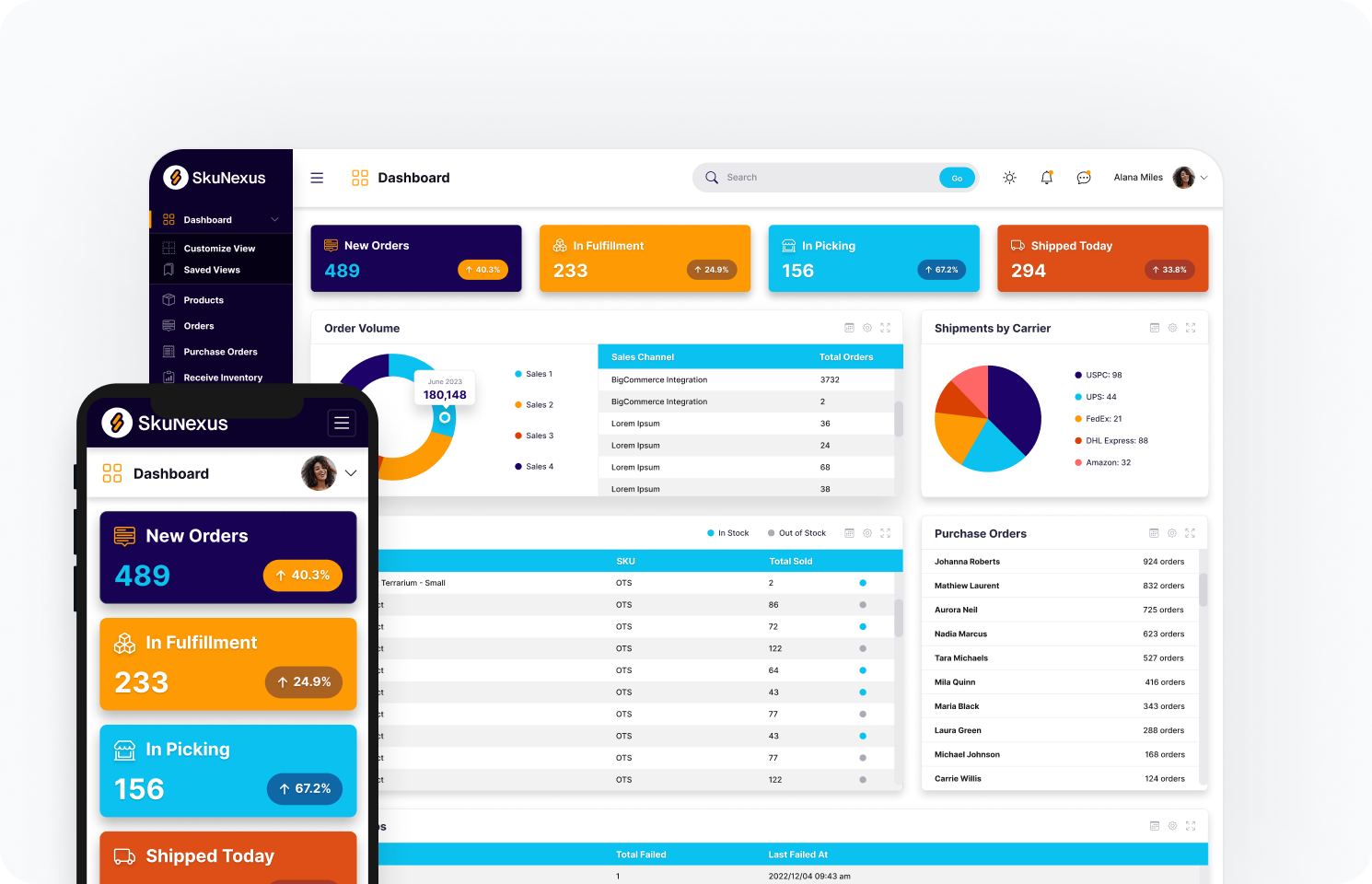

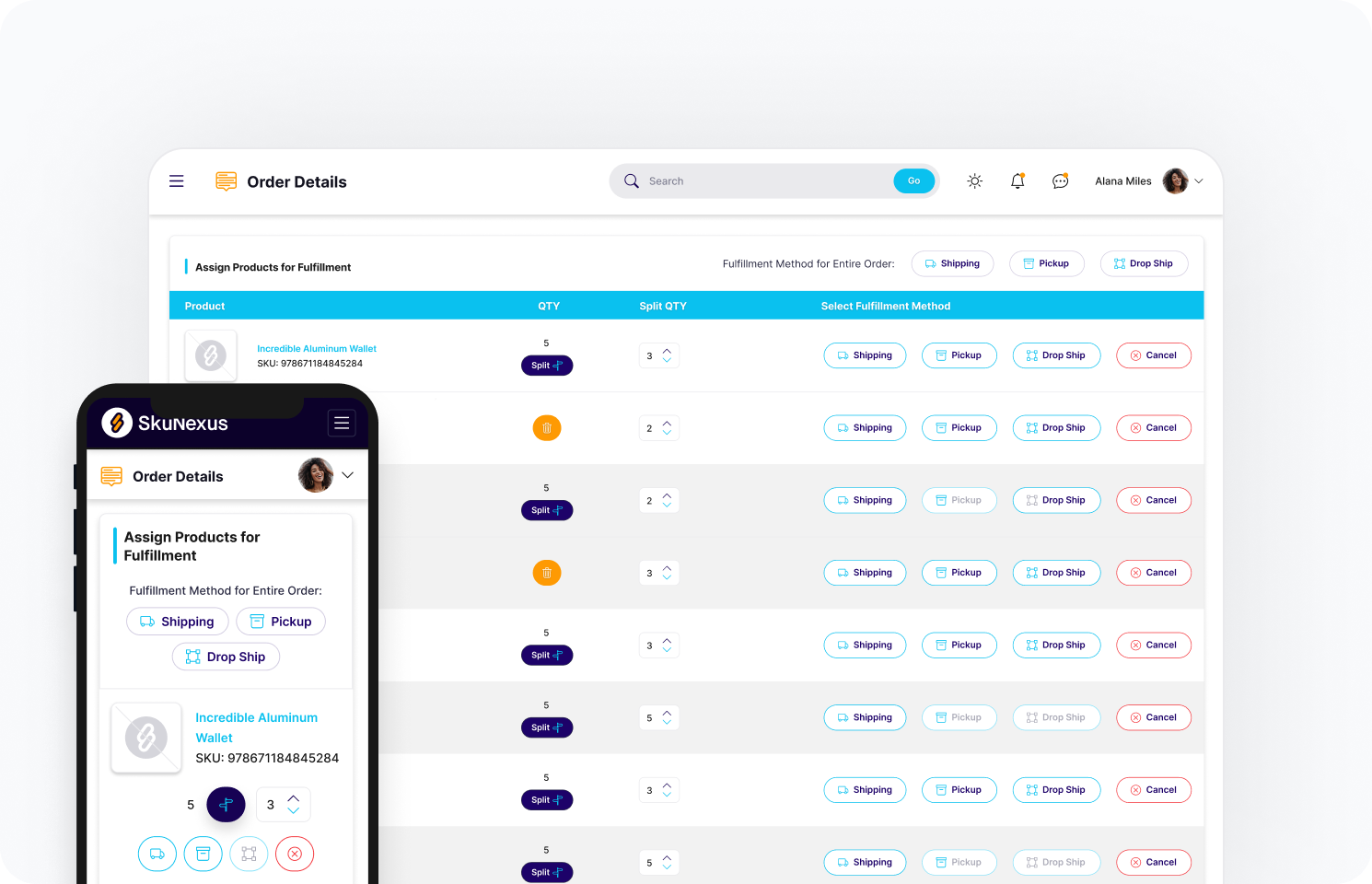

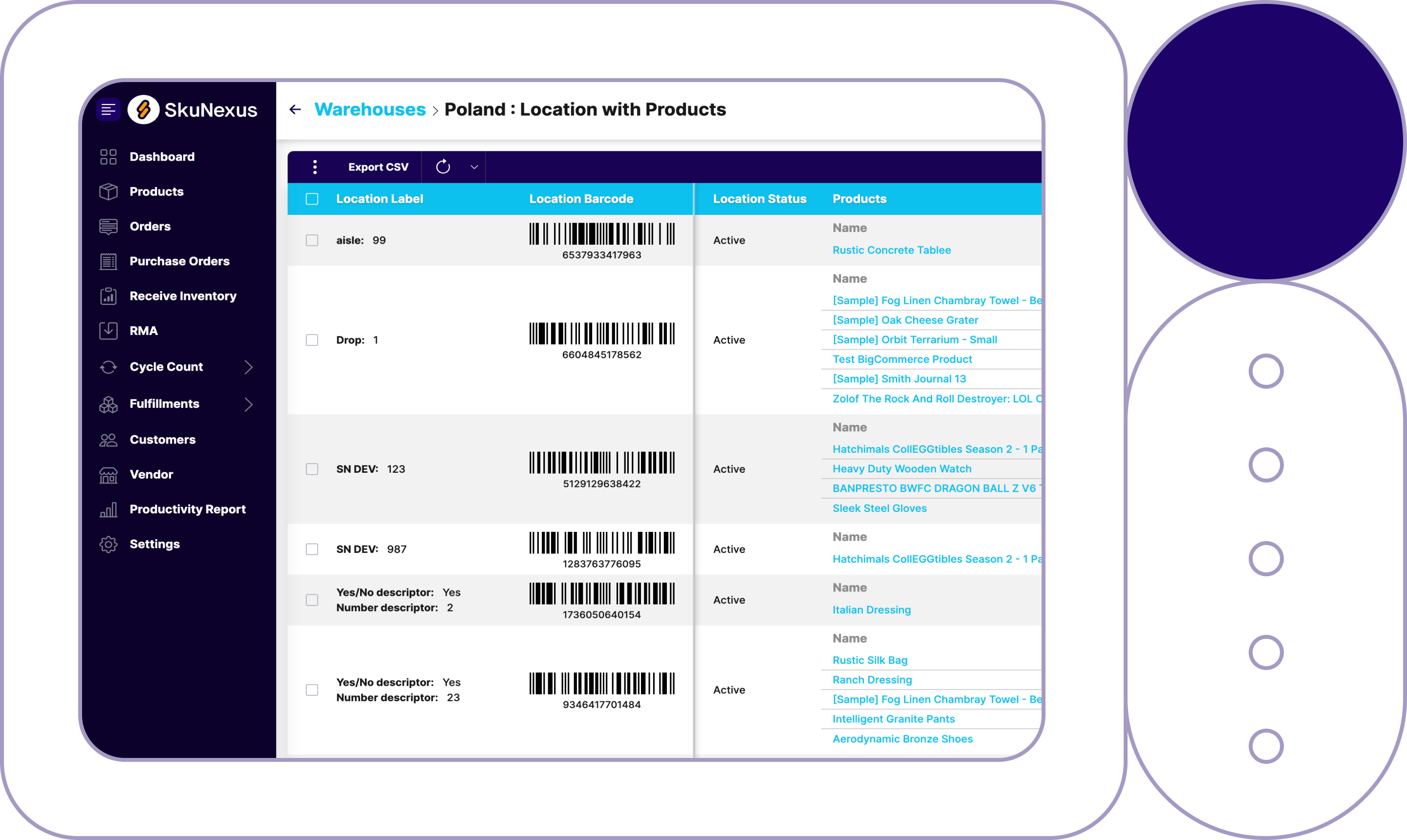

From receiving to putaway to cycle counts, SkuNexus WMS gives you complete visibility and control over every item in your warehouse. Access everything from any device with a browser.

A warehouse management system (WMS) is software that controls and optimizes the movement and storage of goods within your warehouse, from the moment inventory arrives until it's ready to ship.

Trusted by brands running efficient warehouse operations

"We received 500 units yesterday and still can't find half of them."

Without proper putaway processes, inventory disappears into the warehouse. Your team wastes hours searching for items that should be easy to find.

Lost Inventory"Our inventory counts are never right. We did a full count last month and it's already off."

Without regular cycle counts and location tracking, accuracy degrades quickly. Phantom inventory leads to oversells and stockouts.

Inaccurate Counts"Receiving takes forever. Shipments sit on the dock for days before they're put away."

Manual receiving processes create bottlenecks. The longer inventory sits unprocessed, the longer it's unavailable to sell.

Slow ReceivingSkuNexus WMS brings structure to your warehouse. Receiving is streamlined. Putaways are directed. Every item has a location. Cycle counts keep accuracy high. Your team stops searching and starts executing.

See the DifferenceScan, inspect, and process inbound shipments quickly. Inventory is available to sell the moment it's received.

Direct workers to optimal storage locations based on velocity, size, or custom rules. Every item goes where it belongs.

Maintain inventory accuracy with scheduled cycle counts. Catch discrepancies before they become problems.

A 150-year-old premium ice cream brand selling DTC, wholesale, and through national retail partners.

"Our Smoothest Peak Season Ever"

Access full WMS functionality from any device with a browser. No special hardware required.

Paper-based processes might feel familiar, but they cost you time, accuracy, and money every single day.

| Paper and Spreadsheets | SkuNexus WMS |

|---|---|

| ✕ Receiving logged on paper, entered later | ✓ Scan-based receiving, instant availability |

| ✕ Putaway wherever there's space | ✓ Directed putaway to optimal locations |

| ✕ Items stored based on memory | ✓ Every item tracked to exact bin location |

| ✕ Annual counts that shut down operations | ✓ Continuous cycle counting |

| ✕ Continuous cycle counting | ✓ Direct workers to exact locations |

| ✕ Inventory accuracy unknown | ✓ 99.5%+ accuracy, always auditable |

A disorganized warehouse slows everything down. Brands using SkuNexus WMS cut receiving time by 40% and virtually eliminate time spent searching for items. When your warehouse runs smoothly, everything else gets easier.

Free demo • No credit card required

No. SkuNexus WMS runs in any modern browser on any device. Use tablets, phones, laptops, or dedicated terminals. Your existing barcode scanners and label printers work out of the box.

Still have questions?

Talk to Our TeamSee how SkuNexus WMS can transform your receiving, putaway, and inventory accuracy.

SkuNexus is an order management system that allows users full access to the source code, allowing complete control.

7400 Skokie Blvd, Skokie, IL 60077.