SkuNexus is an order management system that allows users full access to the source code, allowing complete control.

7400 Skokie Blvd, Skokie, IL 60077.

How Pleasant Hill Grain replaced broken Magento spaghetti code with Shopware and SkuNexus - gaining real warehouse visibility, wave picking, and the operational confidence to scale.

Get Results Like These

Pleasant Hill Grain is a family-owned eCommerce retailer based in Nebraska, specializing in grain mills, kitchen equipment, baking supplies, and specialty food preparation products. Serving everyone from home bakers to commercial kitchens, they’ve built a reputation on excellent customer service and deep product expertise. With a growing catalog, multi-channel ambitions, and a warehouse operation that had outgrown its tools, they needed a modern platform that could keep up.

Pleasant Hill Grain’s old Magento site was falling apart. Multiple development teams over the years had built mistakes on top of mistakes - what the team called “spaghetti code” that no one could untangle. Every Magento update broke something else. Features stopped working. Inventory counts were wrong.

There was no warehouse management system. Product locations lived in people’s heads. When COVID sent orders surging in 2020, the team had to scramble - building spreadsheets just to keep track of what was coming in and going out. Onboarding new employees meant hoping someone could explain where everything was from memory. They knew they couldn’t keep operating that way.

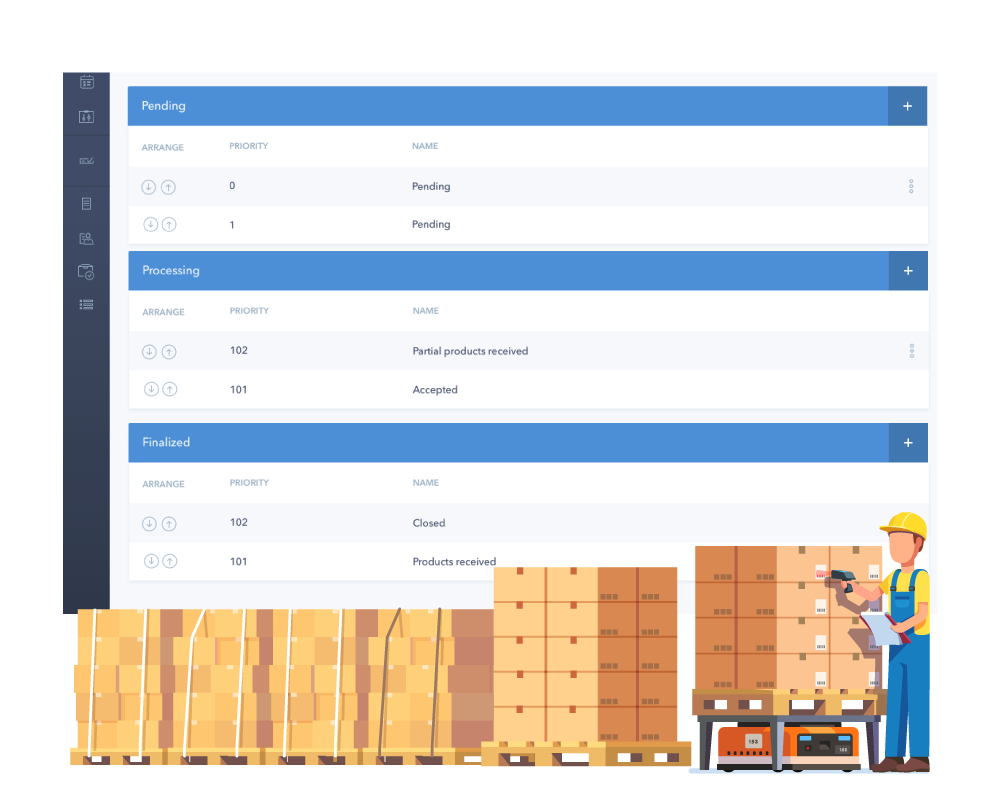

Pleasant Hill Grain migrated their entire operation to Shopware for the storefront and SkuNexus for warehouse and order management - connected through a seamless 360° integration built by Web Solutions.

Migrating from a legacy platform?

Explore Order ManagementSince going live with Shopware and SkuNexus, Pleasant Hill Grain has transformed their operations. Sales are tracking with their best years ever. Returns appear to be down. Employee onboarding is simpler because everything lives in the system instead of people’s heads. And when they think about what happens if order volume doubles, the answer isn’t panic - it’s confidence.

Just having a WMS was a big step for us. More control over where the products are and visibility for the customer service team to see what stage an order’s at in the fulfillment process. We don’t have to rely on people’s brains and memories as much. If our orders increased 100%, I think we’d be better prepared to handle that now.

550K+ pints shipped yearly. 100% order automation. 5+ year partnership.

Read the story Healthcare / D2CZero inventory. Automated PO generation. 100% dropshipped.

Read the story Eyewear / Retail477 locations. 9-month implementation. Full Magento 2 integration.

Read the storyEvery company on this page started with a conversation. Tell us what’s not working - we’ll show you what’s possible.

Get a Demo →SkuNexus is an order management system that allows users full access to the source code, allowing complete control.

7400 Skokie Blvd, Skokie, IL 60077.