In the world of eCommerce, speed and accuracy is the name of the game. In order to attract and keep customers, not only do you need to have an attractive eCommerce site, you need to be able to promise fast and free (or almost free) shipping. Customers are accustomed to receiving their orders almost instantaneously. Warehouse organization is essential to the functioning of a successful business.

While you have probably read about this topic more times than you can count, it cannot be emphasized enough. A disorganized warehouse is a disorganized business. If you are walking in circles looking for inventory, bumping into other workers on your search, or running back and forth across the warehouse floor just to complete the pick of one order, you have a problem. Before you start looking for additional warehouse space, you need to take a long hard look at your warehouse layout and the placement of stock items in said warehouse.

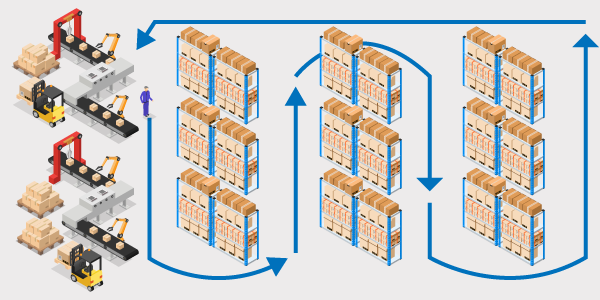

Before you determine where products should be placed in your warehouse, you need to designate space for the following five main stations:

Receiving Station

The receiving station is the starting point for all items in your warehouse. Everything arriving in the warehouse must pass through here. This is where incoming POs are checked for order accuracy. It is also where damaged items can be weeded out from the whole. While marking items off on a checklist will work, the most efficient and accurate way to accomplish this task is to use barcodes and scan everything into your inventory management software.

After receiving items into inventory, a decision must be made where these items should be placed in the warehouse. This is where things can get tricky. If items are placed into any available space, you will end up with a disorganized warehouse. Ideally, you should have warehouse management software that will dictate where those items should be situated.

The aisles and shelves in your warehouse should be clearly labeled in order to eliminate human error. Grouping like items together, and placing seasonal and/or quick selling items in easy to reach areas, will increase your accuracy and efficiency when packing orders. Simply revamping your warehouse layout using these easy suggestions can increase productivity exponentially.

Packing Station

Now that you have picked all the items from a given order, it is time to package them for fulfillment. You need to have a clearly defined packing station. This location will need all the required packaging to prepare any given order. In addition, shipping labels will be printed and affixed to completed orders here.

Staging Station

The staging station is exactly as it sounds - a staging ground. It is the area where all completed orders are placed before being moved to the shipping station. This can simply be skids or carts that transport the packages to the shipping station.

Shipping Station

The shipping station is the point where packaged orders are picked up by the shipping carriers. For maximum efficiency it pays to integrate with numerous shipping carriers to ensure that you always find the fastest and most economical way of shipping your packages. It won’t matter how efficient your pick and pack processes are if your shipping carrier is unreliable. If you are able to choose from multiple carriers, not only will you have the ability to price check, you will also have a backup plan in case one carrier is unable to uphold its promise.

Returns Station

The returns station is the location where returns are processed. According to Invesp CRO, 30% of online purchases are returned. While some companies will have a designated returns station, this is not always necessary. In most cases, the receiving station is able to handle returns as well.

Implementing Change

Implementing these changes can be time consuming and costly. Planning ahead will enable you to execute these changes as quickly and efficiently as possible. The right commerce operations platform directing from behind the scenes will help with that.

SkuNexus is exactly the platform you need! We are an inventory, order, warehouse, and shipping management system all rolled into one. Maintaining an organized warehouse will be a breeze with SkuNexus!

Click here to learn more!